Pressurised steel rotor storage containers provide significant protection when used during either shipping or storage. Manufacturing and construction processes enables the storage containers to be stowed vertically. And as a result, the risk of rotor bowing is prevented, that would otherwise occur during long-term horizontal storage. In the horizontal position, the rotor would sag and detrimentally affect API level rotor balance.

Although these rotor storage containers are closed structures, there is still potential for contamination from outside air including dust and humidity. Consequently, the steel rotor parts would be in the presence of moisture and react with oxygen causing material corrosion. Due to the gelatinous nature of heavier preservatives, they are difficult and time-consuming to remove from rotors. The premier solution, then, for rotor preservation is a nitrogen purge system. Nitrogen functions as an excellent alternative to physical coatings as removal is not required prior to operation. Accordingly, rotor storage containers are frequently equipped with a nitrogen purge system.

The nitrogen purge system, purges atmospheric air. It then replaces the volume of sealed rotor storage containers with commercially pure nitrogen. The rotors are then suited for long-term storage without excessive surface preservation.

These rotor storage containers ensure companies have easy access to essential spare parts. These parts need to be kept on hand for an indeterminate amount of time. They are often difficult to obtain quickly.

In the turbomachinery industry, it is critical to protect and maintain spare rotors to ensure the capability of immediate installation. All components including the following are subject to damage when stored in an area without environmental control.

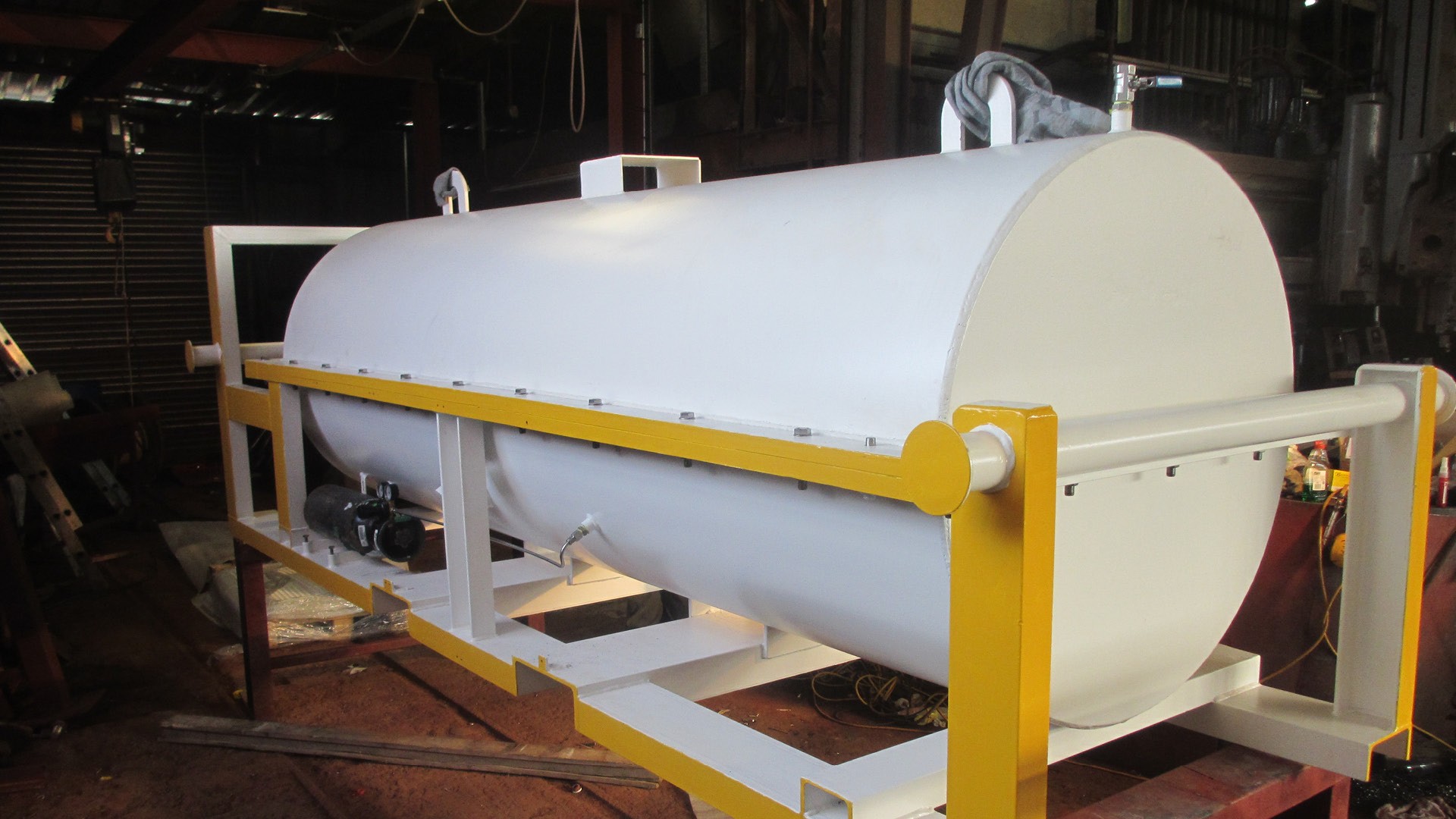

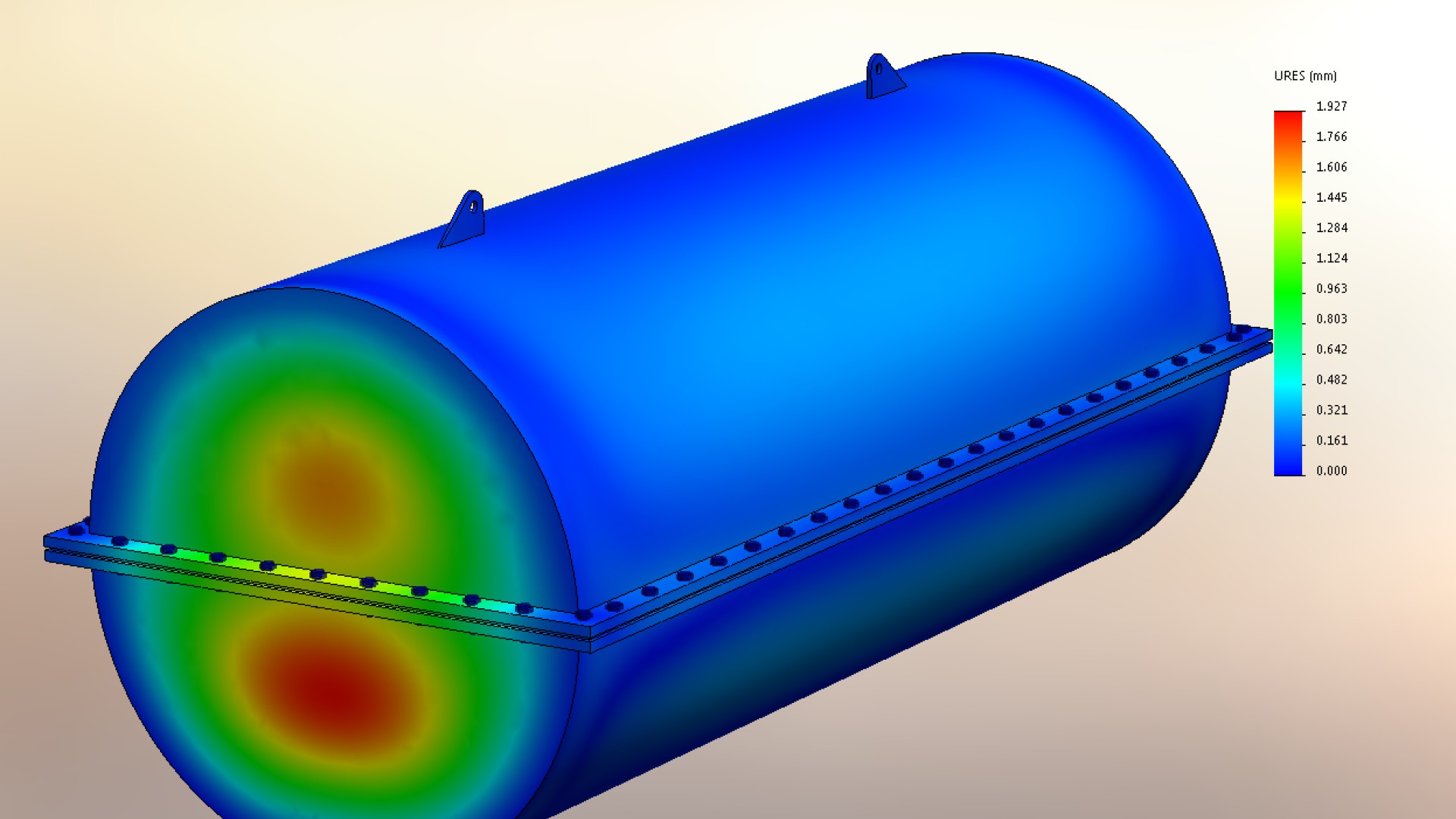

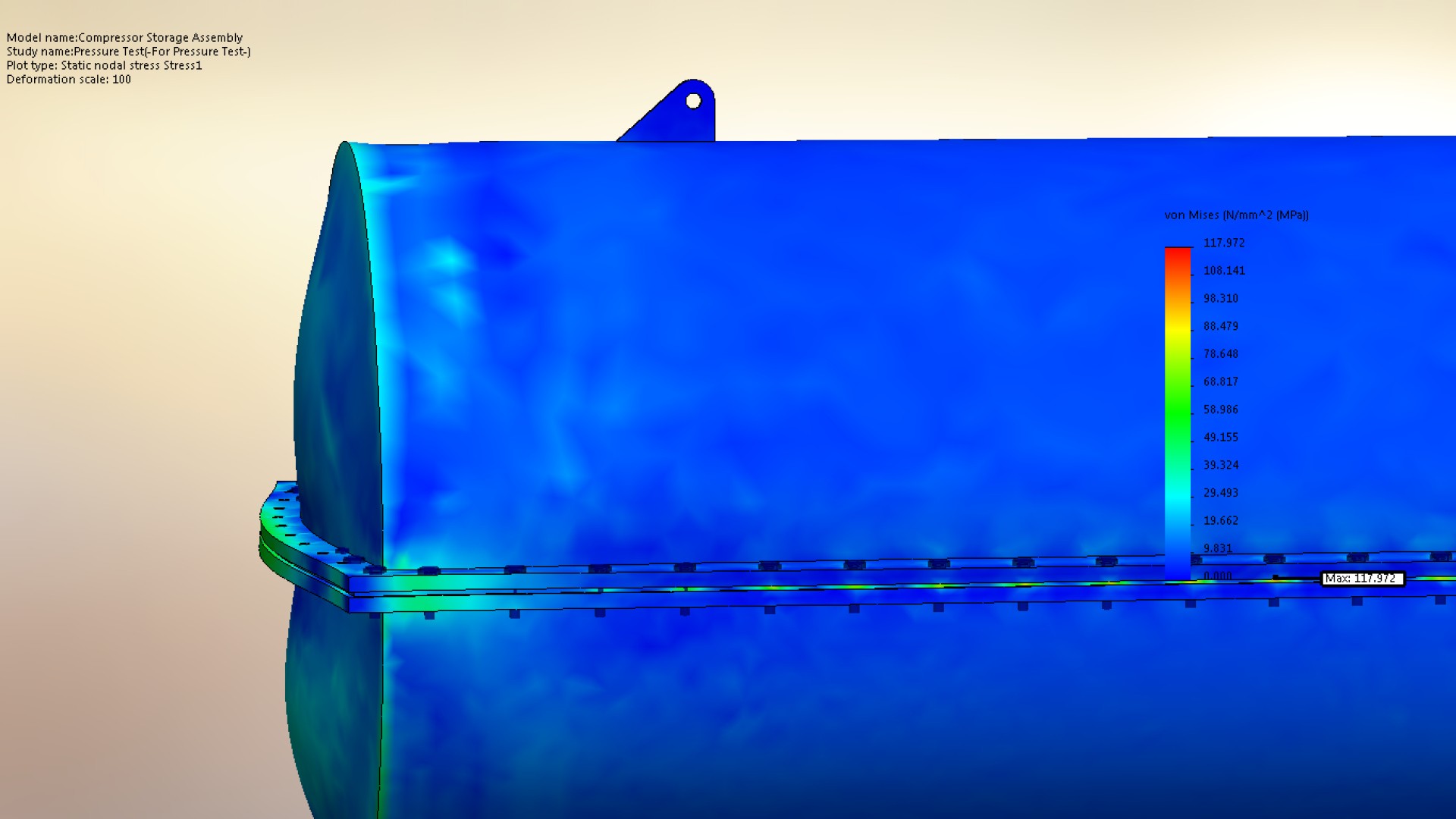

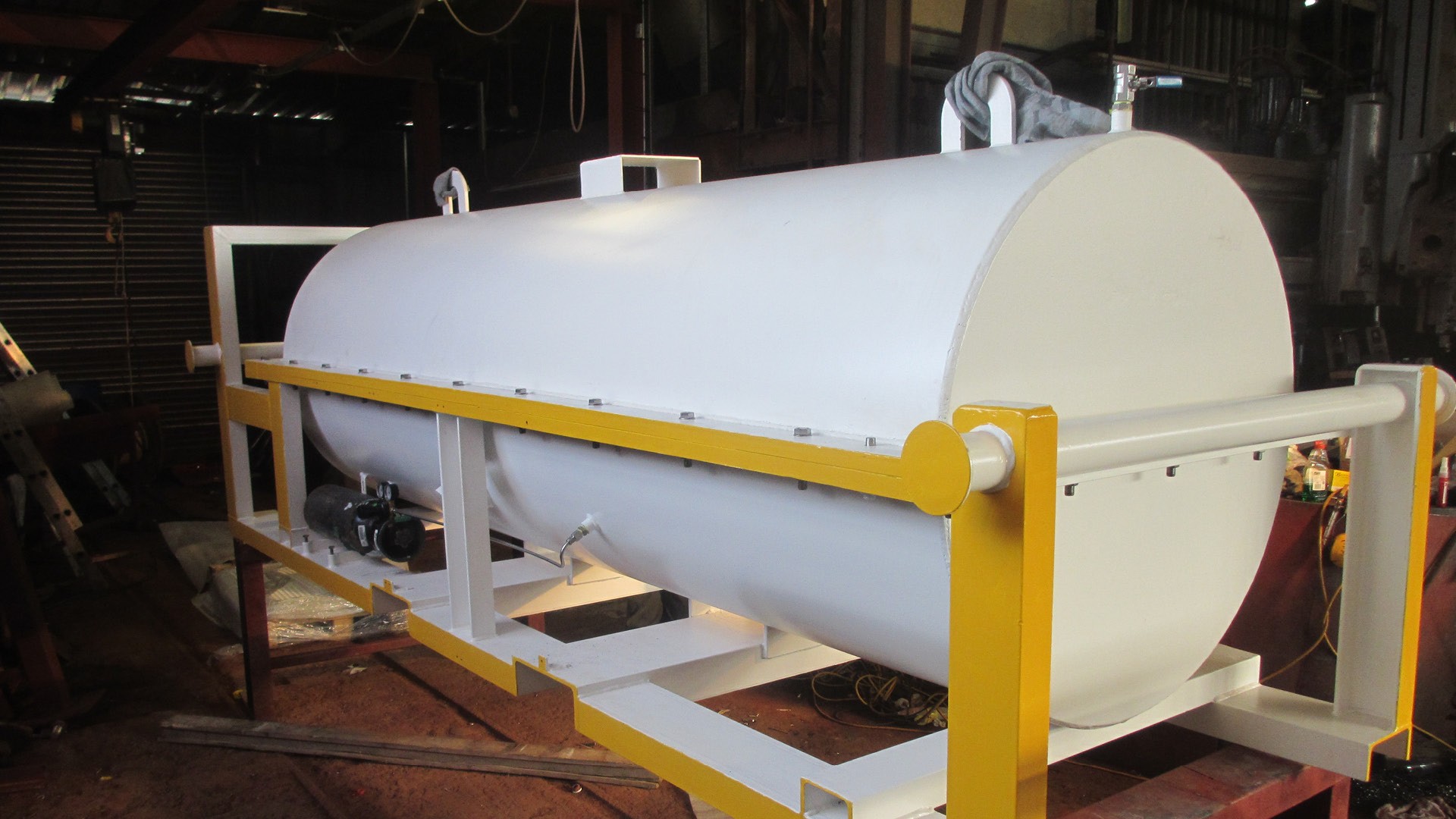

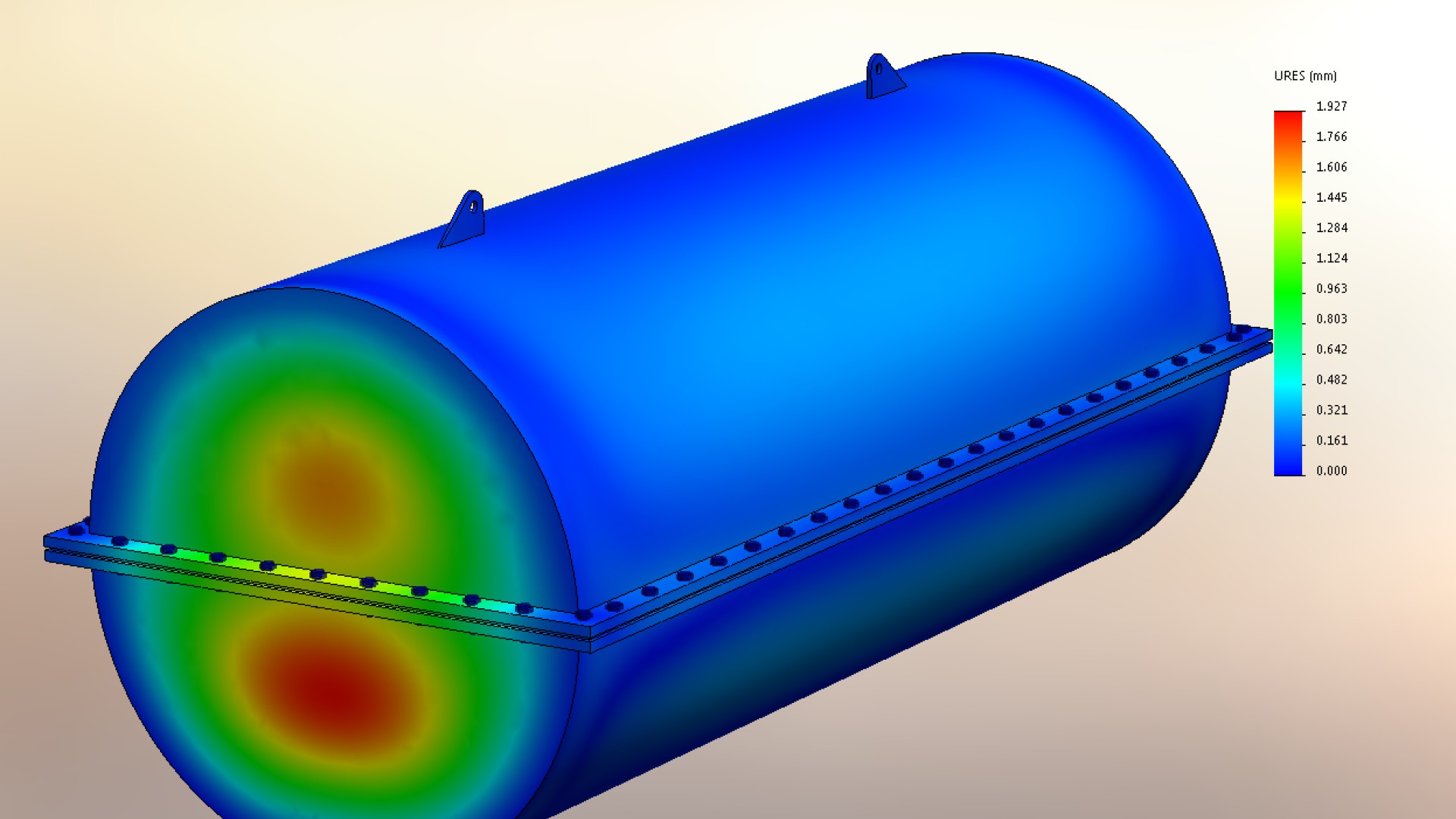

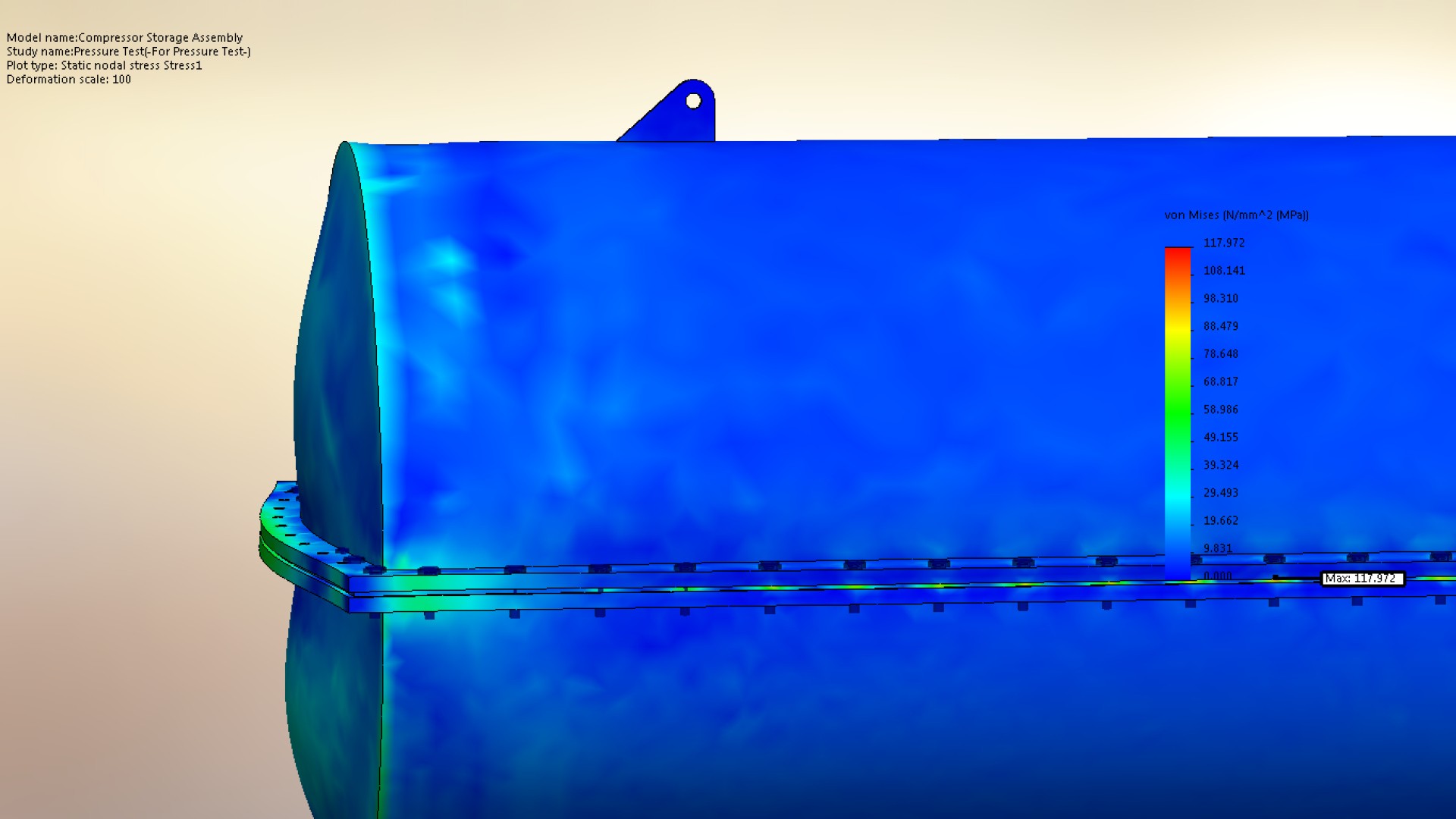

A recent project for us involved the manufacturing of a rotor storage container with a pressure of 1.0 bar. The component had a load of 2,200kg. The container featured a nitrogen bottle attached to its frame. This is to maintain and regulate the pressure and a safety relief valve.

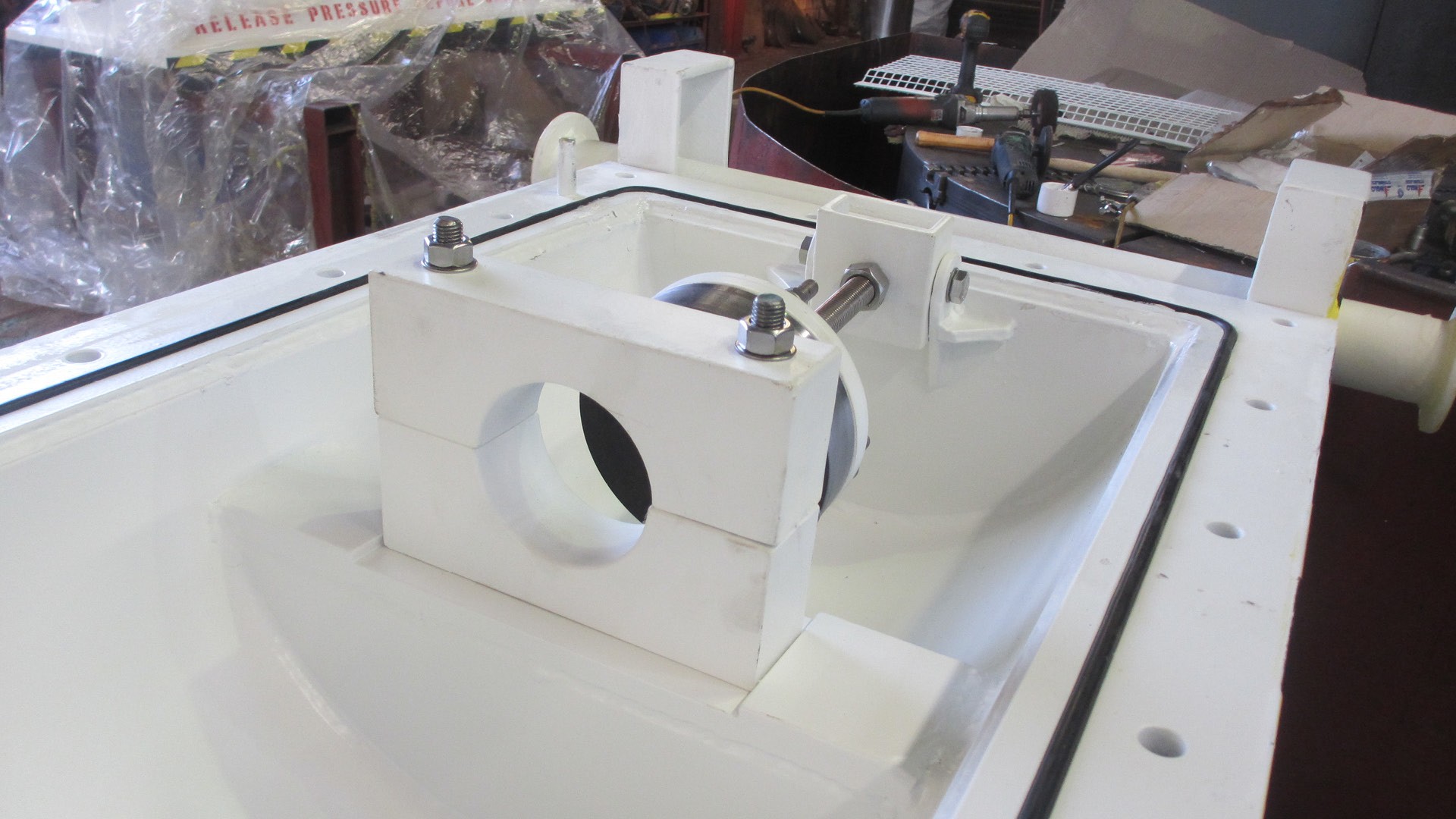

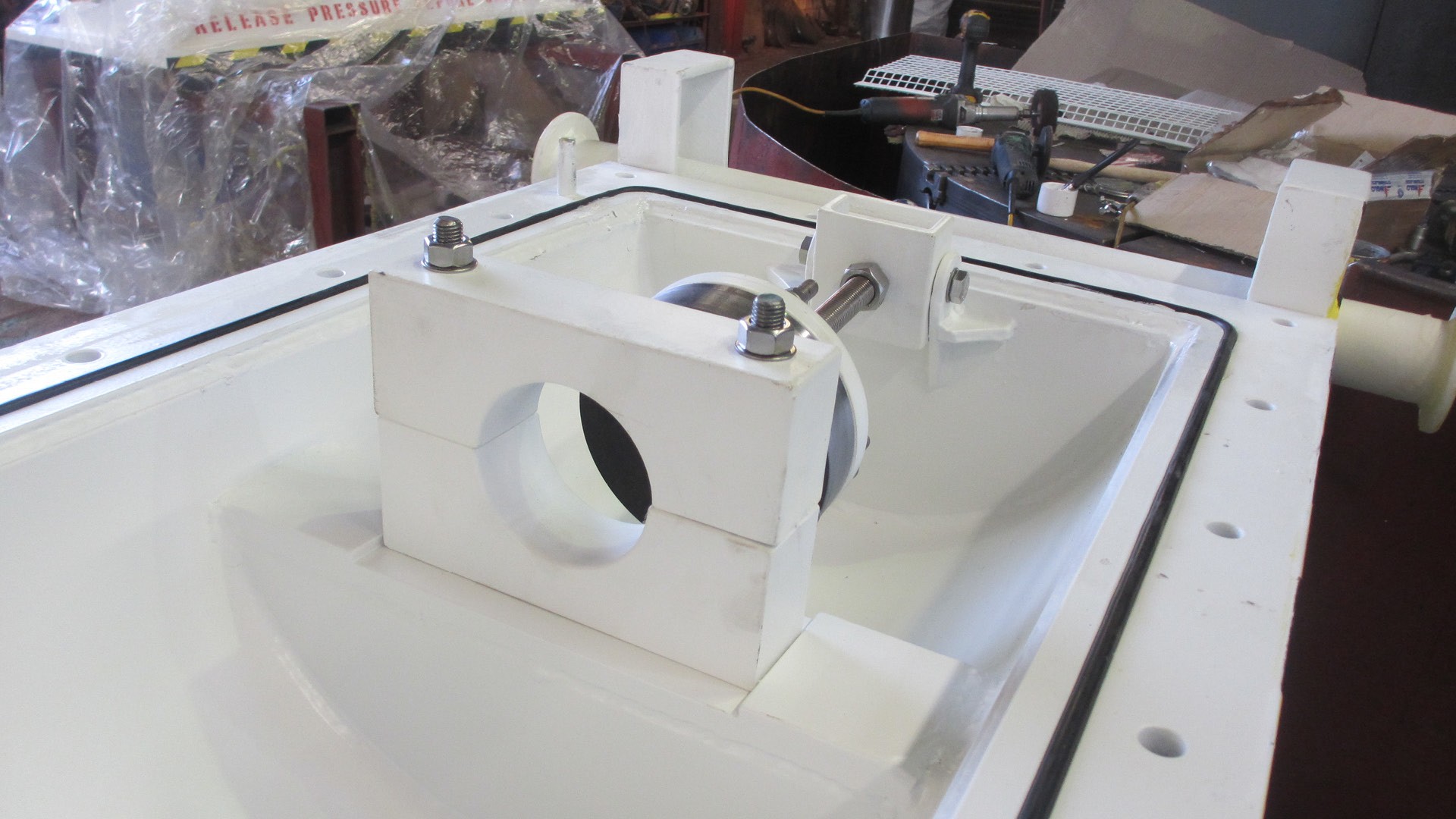

The pressurised rotor storage containers internally feature rubber-faced mounts to secure the stored items in all directions.

To discuss pressurised rotor storage containers or find out how George Green can help your business, please get in touch.

Get in touch